Valves, Fittings & Flanges

- Precision Metal Industry Company

- Services

- Valves, Fittings & Flanges

Valves, Fittings & Flanges

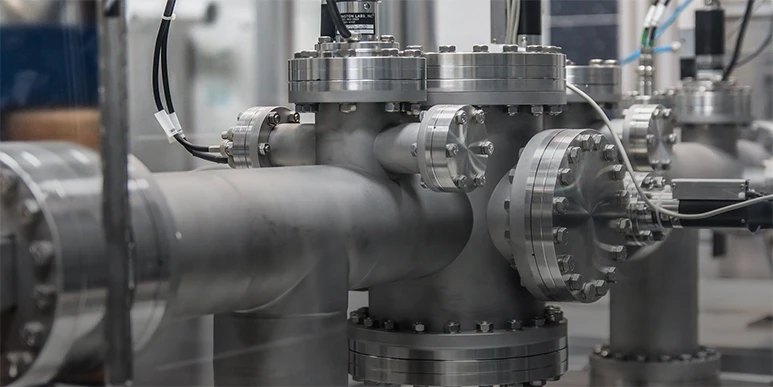

Valves and flanges are essential components of industrial fluid and gas piping systems, where flanges are used to connect valves to pipes and other equipment, facilitating easy maintenance and assembly. Valves regulate, direct, or control the flow of fluids, while flanges provide a strong, mechanical connection that is especially suited for high-pressure, high-temperature, and large-scale systems.

How Anchor Bolts Work

Purpose: Flanges are used to connect pipes, valves, pumps, and other apparatus to form a piping system.

Function: They provide a bolted connection between two components, often with a gasket to create a tight seal.

Flanges Types:

Flanges come in various styles, such as slip-on, weld-neck, and socket-weld, and feature flat or raised faces for different applications.

Applications:

They are used in a wide range of industries, including oil and gas, water treatment, and chemical processing.

Why Choose Us

Flanges

| Flange Type | Welding Neck/Blind/Socket Weld/Lapped Joint/Slip-on/Plate Flange |

| Standard | ANSI/ASME B 16.5, DIN, JIS, AWWA, API, ISO, etc. |

| Material | Carbon Steel — ASTM A105,ASTM A350 LF1,LF2,LF3,A36,ASTM A234 WPB |

| Stainless Steel — ASTM A403 F304/304L, 316/316L, 316Ti, 321, 317L, 310S | |

| Size | NPS from ½’’ to 24’’, CLASS from 150 to 2500 |

| Surface | Light Oiling/Black Painting |

What are Valves?

Purpose:

A valve is a device that controls the flow of a fluid or gas.

Function:

It works by opening, closing, or partially obstructing a passageway to regulate the flow. .

Types:

Common types of valves include ball valves, gate valves, butterfly valves, and globe valves. .

Connection:

Valves are often designed with flanges on both ends to connect to the piping system. .

Relationship Between Valves and Flanges

Integration:

Flanges are a critical part of many valve designs, creating "flanged valves". .

Benefits:

This flanged design allows for easier installation, maintenance, and replacement of valves within a large or complex piping system. .

Durability:

Flanged connections are known for their strength and durability, making them ideal for high-pressure, high-temperature, and large-diameter applications where threaded connections might not be suitable.

Valves

| Marine Butterfly Valve | Size:2″ – 80″ (DN50mm – DN2000mm) Body: ASTM A536 65-45-12, WCB, CF8M Disc: ASTM A536 65-45-12 Nylon coated, CF8, CF8M Seat: NBR, EPDM, PTFE, VITON Stem: SS420, SS431 Body style: Wafer, LUG, Flange Flange: DIN,JIS,ANSI Pressure: PN10,PN16,5K-16K,150-600LB Actuator: Pneumatic, electric, Handwheel, hydraulic Certificate: CCS ABS LR NK BV KR RS |

| Marine Lug Butterfly Valve | |

| Marine Flange Butterfly Valve | |

| High Performance Butterfly Valve | Size: 2″ – 40″ (DN50mm – DN1000mm) Body: ASTM A536 65-45-12, WCB, CF8M Disc: ASTM A536 65-45-12 Nylon coated, CF8, CF8M Seat: RPTFE, PTFE, Metal seal Stem: SS420, SS431 Body style: Wafer, LUG, Flange Flange: DIN,JIS,ANSI Pressure: PN10,PN16,5K-16K,150-600LB Actuator: Pneumatic, Electric, Handwheel, Hydraulic Certificate: CCS ABS LR NK BV KR RS |

| Pneumatic Butterfly Valve | 2″ – 80″ (DN50mm – DN2000mm) |