CNC Machining

- Precision Metal Industry Company

- Services

- CNC Machining

CNC Machining

CNC Machining is a high-precision, automated manufacturing process that uses pre-programmed computer software to control the movement and operation of machinery and cutting tools. It is a subtractive manufacturing method, which means it creates a final product by systematically removing material from a solid block (known as a blank or workpiece) until the desired shape is achieved.

Why Choose Us

How It Works: From Digital to Physical

The CNC machining process transforms a digital concept into a physical component through three main stages.

- CAD (Computer-Aided Design)

- CAM (Computer-Aided Manufacturing)

- Machining

Common Types of CNC Machines

CNC Mills:

These machines use rotating multi-point cutting tools to remove material from a stationary workpiece. They are incredibly versatile and can create a wide variety of features, from simple flat surfaces to complex 3D contours.

CNC Lathes:

In contrast to mills, lathes rotate the workpiece at high speed while a stationary cutting tool removes material. This "turning" process is ideal for creating cylindrical, conical, or spherical parts.

CNC Routers:

Similar to mills but typically used for cutting softer materials like wood, plastics, and composites. They are common in woodworking, sign making, and prototyping.

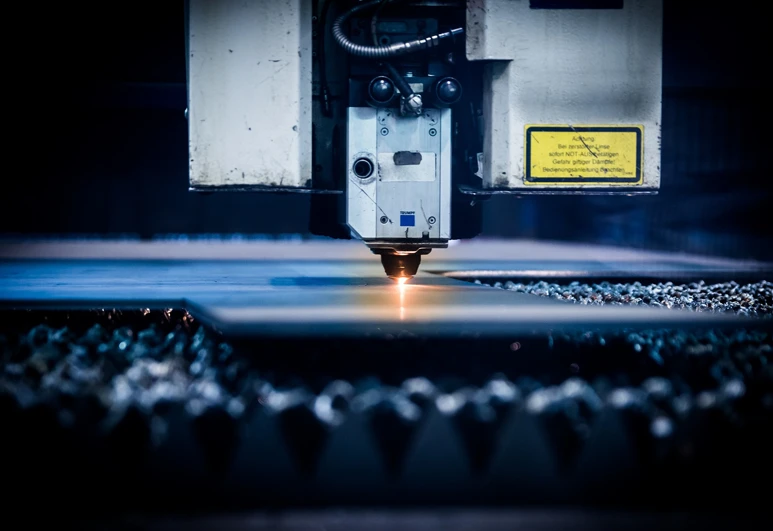

CNC Laser and Plasma Cutters:

These machines use a high-powered laser or a jet of hot plasma to slice through sheet metal and other materials with extreme precision and speed.